Fig 510/511

General Dimensions & Specifications

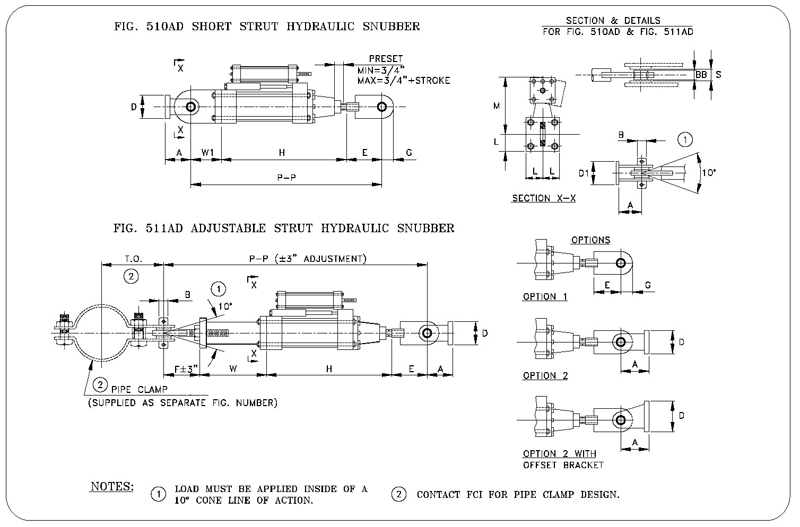

Fig 510AD Short Strut Hydraulic Snubbers

|

|

ORDERING: Specify figure number, description, cylinder size, stroke, load, thermal movement, overall length, and piston end option. If a pipe clamp is required, please specify nominal pipe size or special O.D., pipe temperature, and any additional option features (i.e. integral relief valve or remote reservoir mounting) or special settings required.

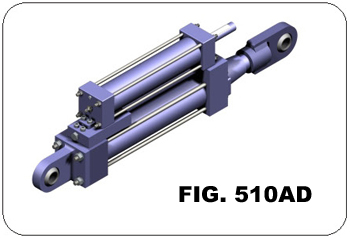

Fig. 510AD – SHORT STRUT HYDRAULIC SNUBBER

| Cylinder | Approx. Weight (1) | H Min. (2) |

P-P Min. (2) | Load Rating (KIPS) | A | B | D | D1 | E | G | L | M | W1 | S | BB | |

| Size | Stroke | |||||||||||||||

| 1 1/2 | 6 | 35 | 16 | 21 | 3 | 2 | 3/4 | 2 1/2 | 2 3/4 | 3 | 1 1/16 | 1 1/4 | 5 | 2 | 3/4 | 0.656 |

| 12 | 42 | 22 | 27 | |||||||||||||

| 18 | 50 | 28 | 33 | |||||||||||||

| 2 1/2 | 6 | 70 | 16 1/2 | 23 1/4 | 10 | 2 1/2 | 1 | 3 | 3 1/2 | 3 3/4 | 1 1/2 | 1 3/4 | 6 | 3 | 1 | 0.875 |

| 12 | 83 | 22 1/2 | 29 1/4 | |||||||||||||

| 18 | 96 | 28 1/2 | 35 1/4 | |||||||||||||

| 3 1/4 | 6 | 125 | 17 3/8 | 27 1/8 | 20 | 4 | 1 1/2 | 5 | 4 3/4 | 5 1/2 | 2 1/2 | 2 1/4 | 7 3/8 | 4 1/4 | 1 1/2 | 1.312 |

| 12 | 145 | 23 3/8 | 33 1/8 | |||||||||||||

| 18 | 165 | 29 3/8 | 39 1/8 | |||||||||||||

| 4 | 6 | 155 | 17 3/4 | 28 1/2 | 30 | 4 | 1 1/2 | 5 | 4 3/4 | 6 1/2 | 2 1/2 | 2 1/2 | 8 1/2 | 4 1/4 | 1 1/2 | 1.312 |

| 12 | 180 | 23 3/4 | 34 1/2 | |||||||||||||

| 18 | 205 | 29 3/4 | 40 1/2 | |||||||||||||

| 5 | 6 | 255 | 18 1/4 | 31 3/4 | 50 | 5 1/2 | 2 | 7 | 6 | 8 | 3 1/2 | 3 1/4 | 10 1/4 | 5 1/2 | 1 7/8 | 1.75 |

| 12 | 290 | 24 1/4 | 37 3/4 | |||||||||||||

| 18 | 325 | 30 1/4 | 43 3/4 | |||||||||||||

| 6 | 6 | 410 | 19 1/2 | 33 3/4 | 70 | 6 | 2 1/4 | 7 | 6 1/2 | 8 1/2 | 4 | 3 3/4 | 11 7/8 | 5 3/4 | 2 1/4 | 1.968 |

| 12 | 465 | 25 1/2 | 39 3/4 | |||||||||||||

| 18 | 520 | 31 1/2 | 45 3/4 | |||||||||||||

| 8 | 6 | 805 | 21 3/16 | 41 7/16 | 130 | 8 1/2 | 3 | 10 | 10 | 12 1/2 | 5 1/2 | 4 3/4 | 16 | 7 3/4 | 2 7/8 | 2.625 |

| 12 | 890 | 27 3/16 | 47 7/16 | |||||||||||||

| 18 | 975 | 33 3/16 | 53 7/16 | |||||||||||||

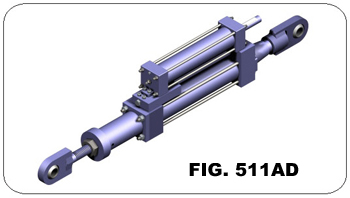

Fig. 511AD – ADJUSTABLE STRUT HYDRAULIC SNUBBER

| CYLINDER | APPROX. WEIGHT (1) | P-P | F | W MIN. | ||

| SIZE | STROKE | MIN. | (4) MAX. | |||

| 1 1/2 | 6 | 40 | 32 3/4 | 100 | 6 1/4 | 7 1/2 |

| 12 | 47 | 38 3/4 | 100 | |||

| 18 | 54 | 44 3/4 | 100 | |||

| 2 1/2 | 6 | 75 | 36 1/4 | 120 | 7 1/4 | 8 3/4 |

| 12 | 90 | 42 1/4 | 120 | |||

| 18 | 105 | 48 1/4 | 120 | |||

| 3 1/4 | 6 | 130 | 41 5/8 | 120 | 9 1/2 | 9 1/4 |

| 12 | 150 | 47 5/8 | 120 | |||

| 18 | 170 | 53 5/8 | 120 | |||

| 4 | 6 | 200 | 44 1/8 | 120 | 10 1/8 | 9 3/4 |

| 12 | 225 | 50 1/8 | 120 | |||

| 18 | 250 | 56 1/8 | 120 | |||

| 5 | 6 | 330 | 49 1/2 | 120 | 12 1/2 | 10 3/4 |

| 12 | 365 | 55 1/2 | 120 | |||

| 18 | 400 | 61 1/2 | 120 | |||

| 6 | 6 | 530 | 53 3/8 | 120 | 13 3/4 | 11 5/8 |

| 12 | 590 | 59 3/8 | 120 | |||

| 18 | 645 | 65 3/8 | 120 | |||

| 8 | 6 | 1050 | 62 11/16 | 120 | 16 1/4 | 13 3/8 |

| 12 | 1140 | 68 11/16 | 120 | |||

| 18 | 1225 | 74 11/16 | 120 | |||

| Fig. 510AD & 511AD: Dimensions | ||||

| CYLINDER SIZE | A | Fig. 510AD P-P Retracted1 | Fig. 511AD P-P Retracted1 | MAX.RECOM. NORMAL LOAD2 (lb.) |

| 1 1/2 | 2 | 21 | 32 3/4 | 3,000 |

| 2 1/2 | 2 1/2 | 23 1/4 | 36 1/4 | 10,000 |

| 3 1/4 | 4 | 27 1/8 | 41 5/8 | 20,000 |

| 4 | 4 | 28 1/2 | 44 1/8 | 30,000 |

| 5 | 5 1/2 | 31 3/4 | 49 1/2 | 50,000 |

| 6 | 6 | 33 3/4 | 53 3/8 | 70,000 |

| 8 | 8 1/2 | 41 7/16 | 62 11/16 | 130,000 |

| 1Add cold piston setting for install length. These values reflect cylinders having 6″ of stroke. 2Load must not be applied utisde 10º included angle cone of action to the pipe clamp axis w/o special authorization. |

||||

|---|---|---|---|---|

Applications & Industries Served

Ammonia Plant

Chemical Plant

Clean Fuels

Commercial

Chemical Plant

Clean Fuels

Commercial

Electric Plant

Energy Facility

Ethylene Plant

LLDPE Chemical Plant

Energy Facility

Ethylene Plant

LLDPE Chemical Plant

LNG Plant

MTBE Plant

Natural Gas Combined Cycle Facility

Natural Gas Processing & Separation

MTBE Plant

Natural Gas Combined Cycle Facility

Natural Gas Processing & Separation

Oil Refinery

Oil Sand Mine

Paper Manufacturer

Oil Sand Mine

Paper Manufacturer